It is to induce a current within a conductor by changing the magnetic field is through electromagnetic induction and melt the metals.

Vacuum induction melting furnace meaning.

When the metal becomes molten this field also causes the bath to move.

Eddy currents create heating effects to melt the metal.

The induction furnace is connected to an ac power source at a frequency precisely.

This is called inductive stirring.

Induction heating induces eddy currents within conductors.

High temperature graphitization furnace is mainly used for battery anode material carbon material structural parts products c c composite material products carbon fiber carbon material carbon fiber rope sintering high temperature graphitization of phosphorus graphite and other graphite materials and others.

Cu fe ni co al.

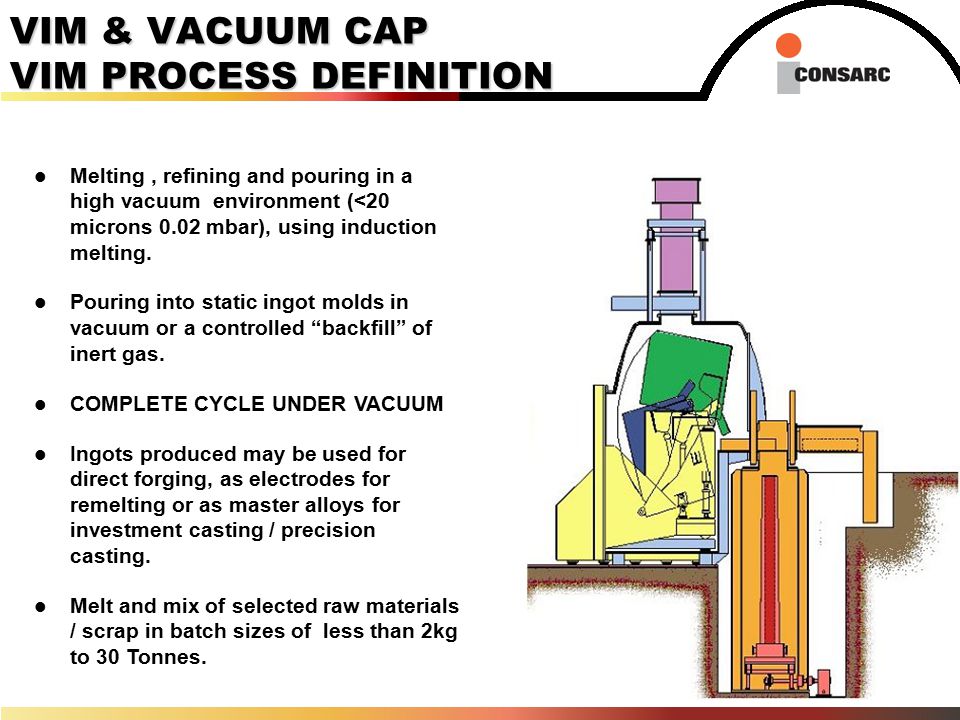

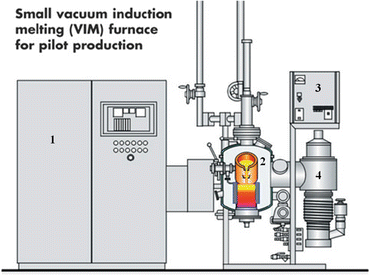

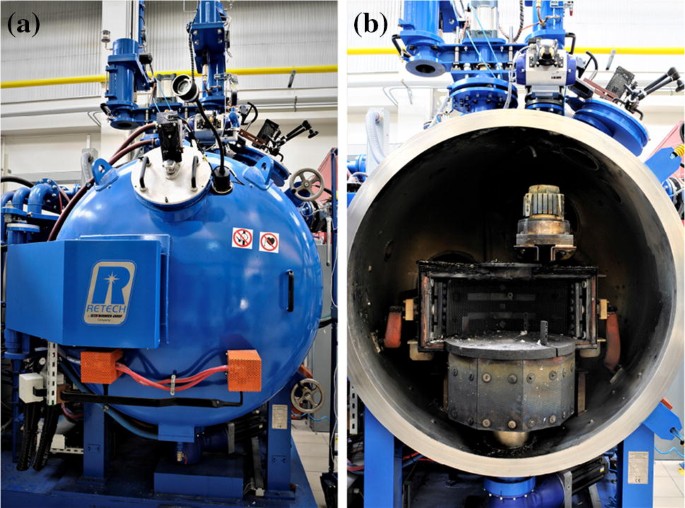

The vim vacuum induction melting furnace is a tool dedicated to the elaboration of materials.

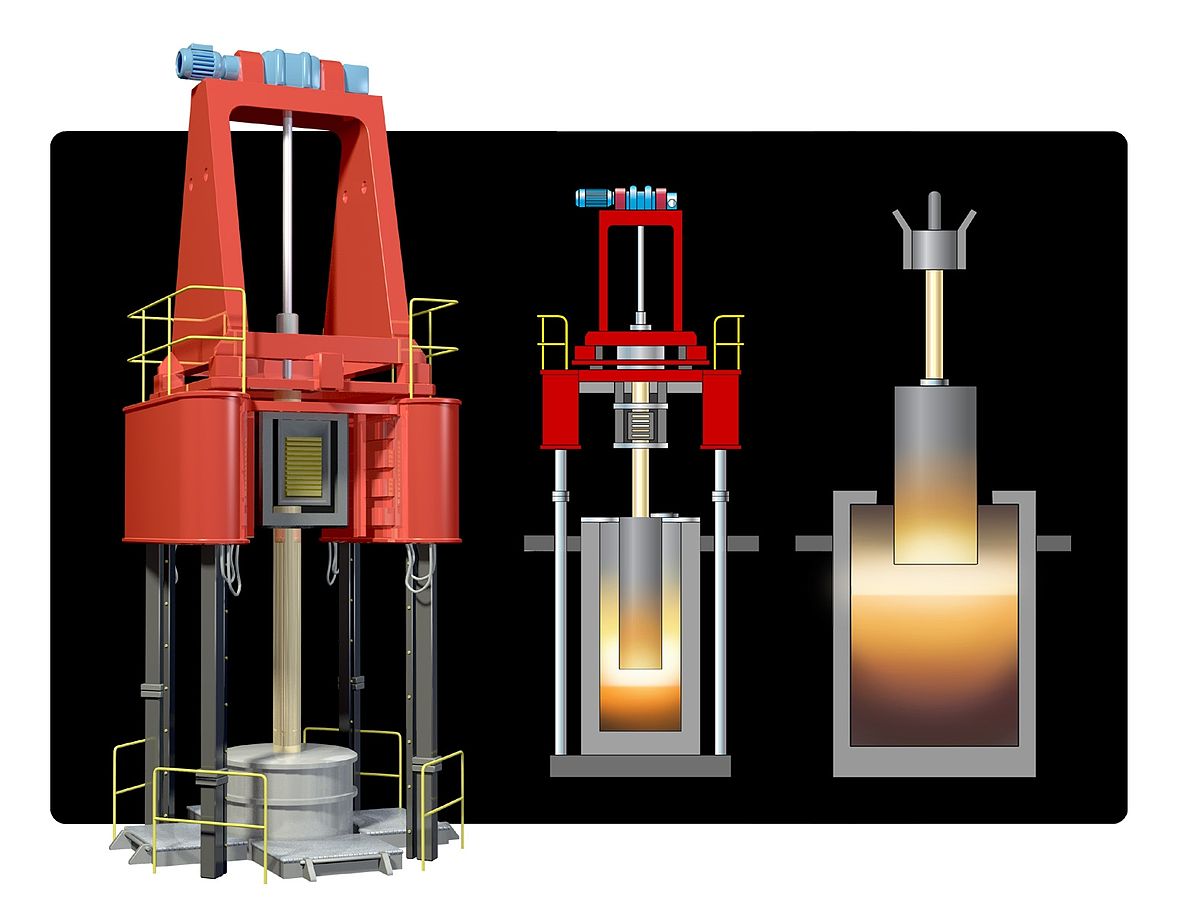

Steel billet making systems.

High resistance load hrl melting systems.

Vacuum induction melting systems.

Induction systems for vacuum and controlled atmospheres.

In an induction furnace the metal charge material is melted or heated by current generated by an electromagnetic field.

Vacuum induction heating graphitization furnace equipment function principle.

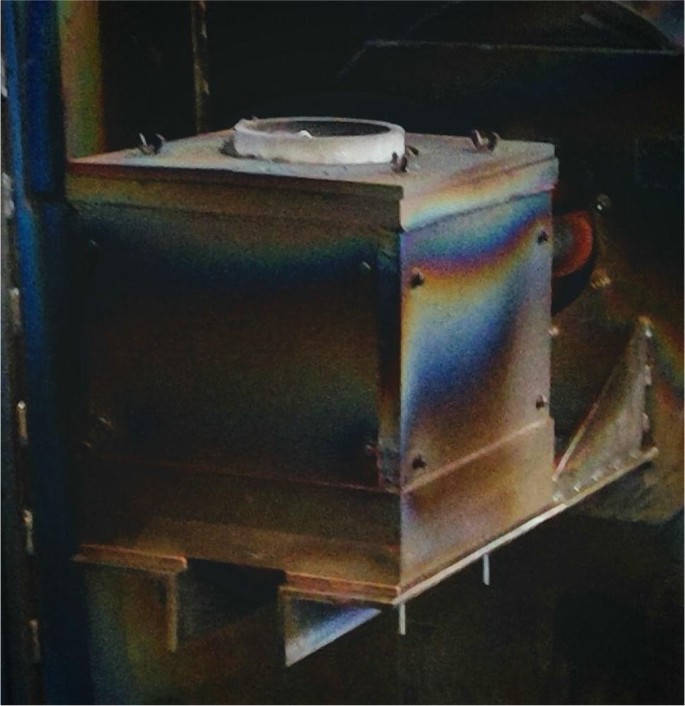

An induction furnace containing a refractory lined crucible surrounded by an induction coil is located inside a vacuum chamber.

Important smelting equipment for producing nickel based superalloy titanium alloy non ferrous metal stainless steel ultra high strength steel and other special alloy materials.

The vacuum induction melting furnace is a high temperature heating equipment used for smelting and melting nickel cobalt nickel iron and other metals all these are done in a protective atmosphere.

Electrical eddy currents are used to make the melting process possible.

Vacuum induction melting vim utilizes electric currents to melt metal within a vacuum.

Ladle refining furnaces lrf.

Vacuum induction melting furnace high temperature vacuum induction melting furnace medium frequency up to 2000 this vacuum induction melting furnace adopts the theory of medium frequency induction heating and builds a high vacuum system so that the metal could be melted under a high vacuum situation.

Enjoy the latest technologies for melting.

Drying and preheating systems.

The first prototype was developed in 1920.

Power window ladle systems.

This constant motion naturally mixes the bath producing a more homogeneous mix and assists with alloying.

Vacuum induction melting vim is the melting of metal via electromagnetic induction under vacuum.